Routine Repair That Keeps Your Wind Turbines Rotating

With the skills needed to handle your wind turbine maintenance, you will always be able to breathe easy knowing that your machine is in the hands of our skilled machinists.

Trust that the team working on your wind turbine parts has the knowledge and experience to do it right. You’ll always be able to breathe easy knowing that you’re in capable hands with Sadler Machine.

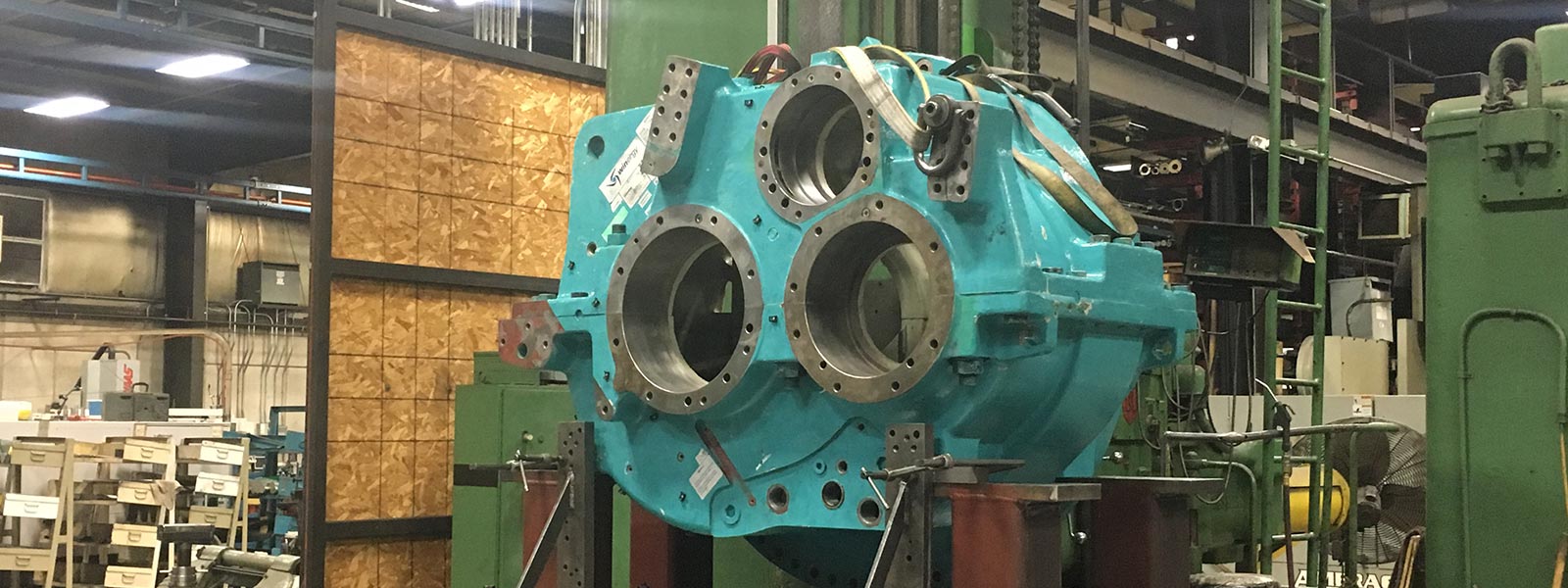

Wind Turbine component repair capability includes:

- Main shafts, HVOF (high velocity oxygen fueled) spray process which involves undercutting and coating bearing diameters to O.E.M specifications, including inboard and outboard diameters.

- Gear boxes, Sleeving or plating of low speed, intermediate, and high-speed bores is performed in-house on a regular basis at Sadler Machine. Fretting repairs and re-facing of planet faces is also included in our gear box repair repertoire.

- Main shafts, Undercut process, where bearing diameter(s) are reduced facilitating the use of alternate bearing sizes.

- Planet carrier repair, upwind and downwind (pin bores, caps and journals) are repaired typically using one or more of five methods, sleeving, HVOF coating welding, plating and boring.

- Main shafts, Rework capabilities include performing “deep-roll” and burnishing processes. Lathe capacity allows Sadler to repair main shafts up to 28,000 pounds.

- Main seals and covers, repair or replacement of discontinued or hard to find components to O.E.M. specifications are not beyond the scope of our capabilities.

Efficient and Effective

Don’t let slow and unqualified maintenance result in too much downtime and lost profit. Everyone at Sadler Machine understands your need to get your wind turbine up and running. We’ve made it our goal to meet your expectations on every job through reliable, honest, and professional service.

The Space Needed for Your Job

While choosing somebody who has the know-how to handle your wind turbine repair is essential, it’s just as important that you find somebody who has the space to do it correctly. With over 60,000 sq. ft. of space, our manufacturing facility has the room and equipment to accurately complete your job.

Serving Industries of All Types

Since 1956 you’ve been able to depend on our team to handle all your fabrication projects, no matter what size they might be.

Over 65+ years of experience has not only provided us with the skill to proficiently get your job done right, but also taught us the importance of providing 100% customer satisfaction on every job, every time.

- Short Run / Prototype

- Maintenance / Job Shop Machining

- Fabrication

- Gear Boxes & Air Locks

- Sub Contact Services

- Pulp & Paper

- Inventory Stock Management

- Building

- Large Part Machining

- Grinding

- Stress Relieving & Heat Treating

- Information Technology

- Machinery

- Manufacturer Supply